EASY TO TALK ABOUT TOMOGRAPHY: HOW MUCH DO WE REALLY KNOW ABOUT THESE TECHNIQUES?

Pubblicato da Brigida Michele in Xrayconsult · Domenica 15 Set 2024 · 25:30

Tags: Tomography, Techniques, X, rays, 3D, images, Non, destructive, testing, NDT, Internal, defects, Quality, Safety, Gas, turbines, Automotive, engines, Predictive, maintenance, Downtime, Maintenance, costs, Research, Development, Production, Manufacturing, processes, Industrial, products

Tags: Tomography, Techniques, X, rays, 3D, images, Non, destructive, testing, NDT, Internal, defects, Quality, Safety, Gas, turbines, Automotive, engines, Predictive, maintenance, Downtime, Maintenance, costs, Research, Development, Production, Manufacturing, processes, Industrial, products

Easy to talk about Tomography:

How much do we really know about these techniques?

Introduction to Tomographic Techniques The Different Tomographic Techniques

- Computed Tomography (CT or CT)

- Cone Beam Computed Tomography (CBCT)

- Positron Emission Tomography (PET)

- Single Photon Emission Computed Tomography (SPECT)

- Electron Beam Computed Tomography (EBCT)

- Dual Source Computed Tomography (DSCT)

- Micro-Computed Tomography (micro-CT)

- Nano Computed Tomography (Nano-CT)

- Dual-Energy Computed Tomography (DECT)

- Laminography (CL)

- Single Photon Emission Computed Tomography Computed Tomography (SPECT/CTA)

Benefits and Future Prospects Conclusion

- Introduction to Tomographic Techniques in Industrial Applications: A Critical Overview

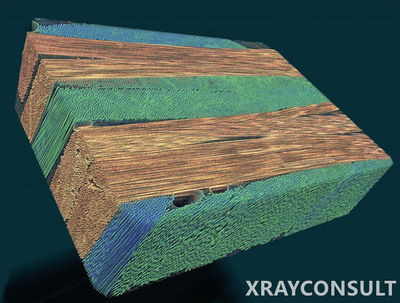

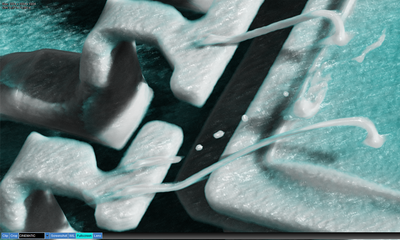

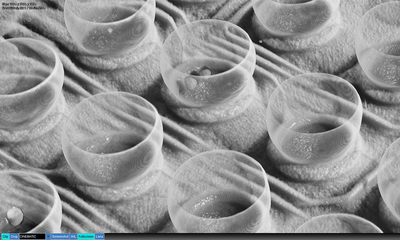

Tomographic techniques represent one of the most advanced frontiers in the field of non-destructive testing (NDT), offering innovative tools for the inspection and analysis of industrial materials and components.Originally developed for medical use, these technologies have been adapted and refined to address the challenges of modern industry, enabling high-resolution three-dimensional imaging without compromising the integrity of the examined objects.These techniques use various types of radiation, such as X-rays, to penetrate materials and create detailed images that reveal internal structures and potential hidden defects."Micro Tomography - Visualization of Fiber Arrangement"In an increasingly complex and competitive industrial environment, ensuring product quality, safety, and reliability has become essential.Tomographic techniques address this need by enabling in-depth analysis of critical components and complex structures.For example, they can be used to inspect gas turbines, identifying internal cracks or fusion defects that could compromise operational safety and engine performance.Similarly, in the automotive industry, tomography is employed to analyze engines and mechanical components, ensuring that finished products meet stringent quality and safety standards.

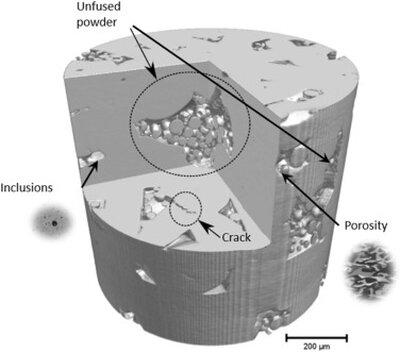

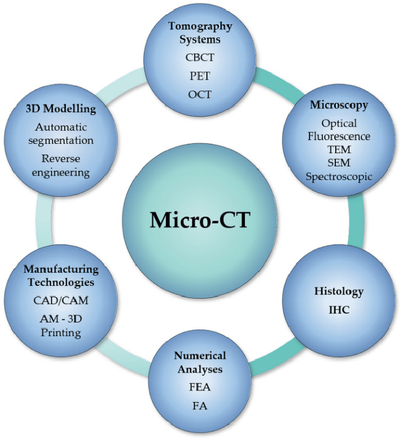

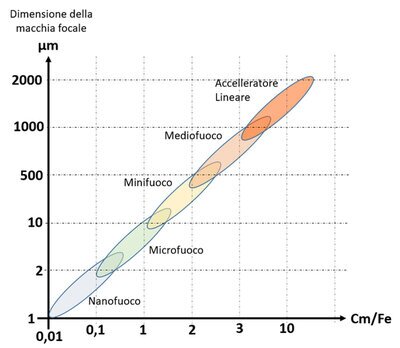

"Types of Defects in a Tomographic Volume "The potential of tomographic techniques goes beyond mere defect identification.They provide essential data for fault prevention and predictive maintenance, helping to reduce machine downtime and maintenance costs.Detailed three-dimensional images allow engineers to better understand the structural integrity of materials and components, facilitating the design of safer and more reliable products.Beyond traditional applications, tomographic techniques are opening new frontiers in industrial research and development.For example, in the materials industry, tomography is used to study the microstructure of composite materials and metals, allowing for optimization of production processes and enhancement of material properties.In the field of 3D printing, these techniques are employed to inspect printed components, identifying printing defects such as porosity and misalignments that could compromise the final product quality.Tomographic technologies not only improve the efficiency of production processes but also contribute to technological innovation."Micro-Tomography and Interaction with Other Sectors"With the ongoing evolution of these techniques, new applications are emerging in sectors such as aerospace, electronics, energy, and pharmaceuticals, expanding the possibilities for non-destructive inspection and analysis.Furthermore, the integration with artificial intelligence and machine learning promises to further enhance the capabilities for image analysis and interpretation, making these technologies even more effective and versatile.In summary, tomographic techniques represent a crucial component in the field of non-destructive testing, offering advanced solutions for the inspection and analysis of industrial materials.With their ability to provide detailed three-dimensional images and monitor processes in real-time, these technologies are revolutionizing production processes, improving product quality and safety.As technological advancements continue, the applications of tomographic techniques are set to expand further, contributing significantly to industrial innovation and efficiency."Table of Different Systems with Focal Spot Size and Penetration"Tomography encompasses various advanced imaging techniques that use different methods to obtain detailed images of the internal structures of biological and industrial objects.

- The Different Tomographic Techniques

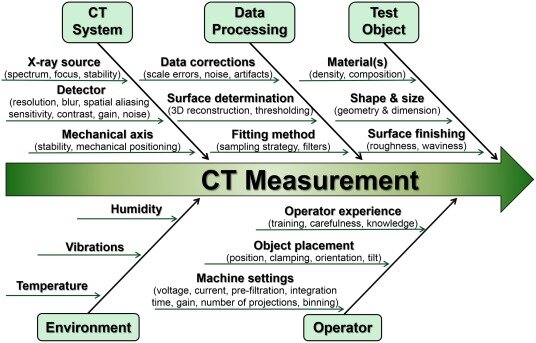

These techniques are essential in the medical field for diagnosing and monitoring diseases, but they also have applications in industrial contexts for material and component analysis.Below are the tomographic techniques, which can be explored further through the provided link."Tutte le fasi utilizzate per la misura con la Tomografia"1. Computed Tomography (CT)Computed Tomography (CT) is an advanced imaging technology that uses X-rays to create detailed three-dimensional images of objects and structures.Originally developed for medical applications, CT has been adapted to meet industrial needs, where it is used to examine critical components and complex structures without causing damage.This method is essential for non-destructive analysis of materials and products, allowing engineers to visualize and analyze the internal integrity of objects with great precision.For example, CT is used to inspect gas turbines, which are crucial components in power plants and aircraft engines.

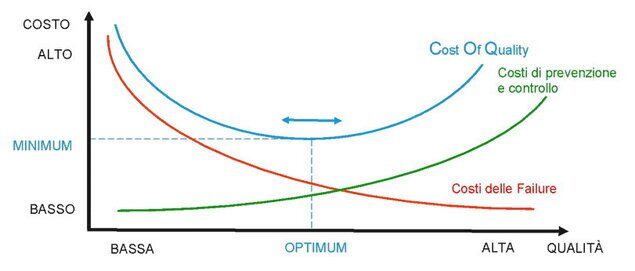

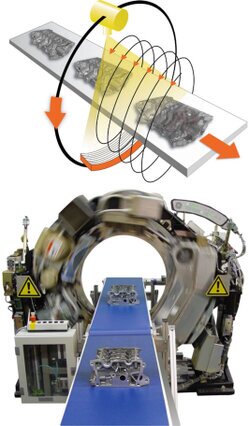

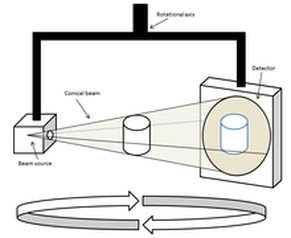

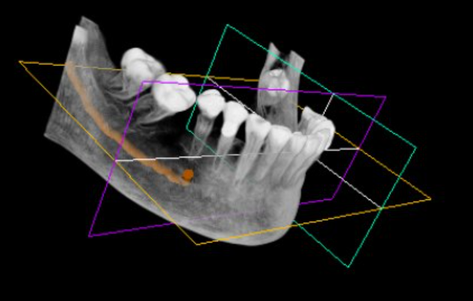

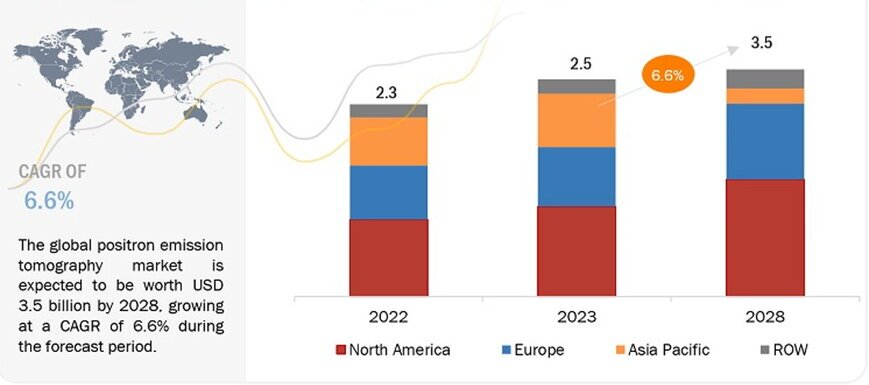

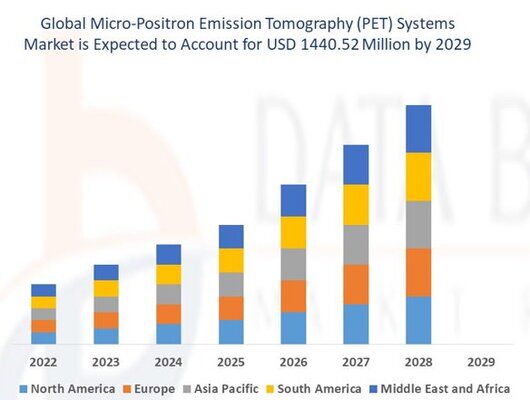

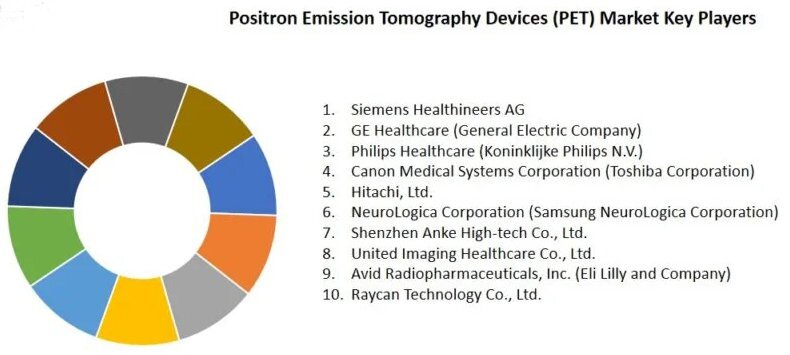

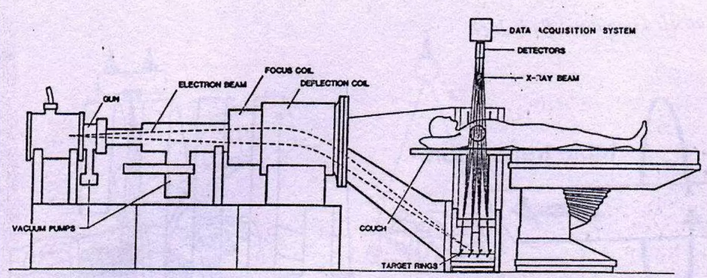

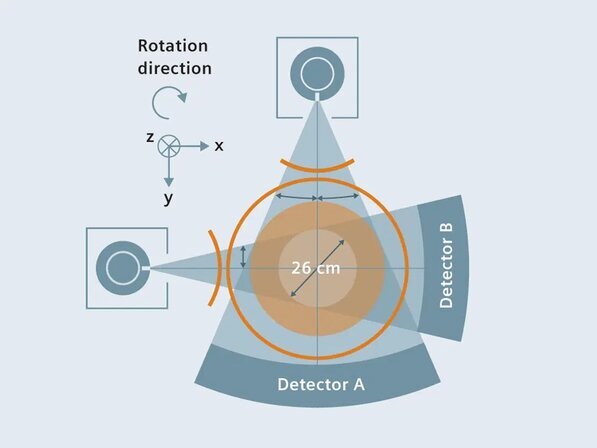

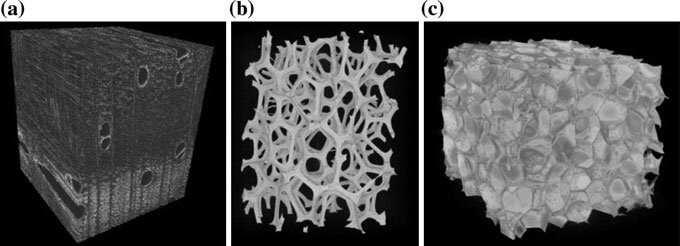

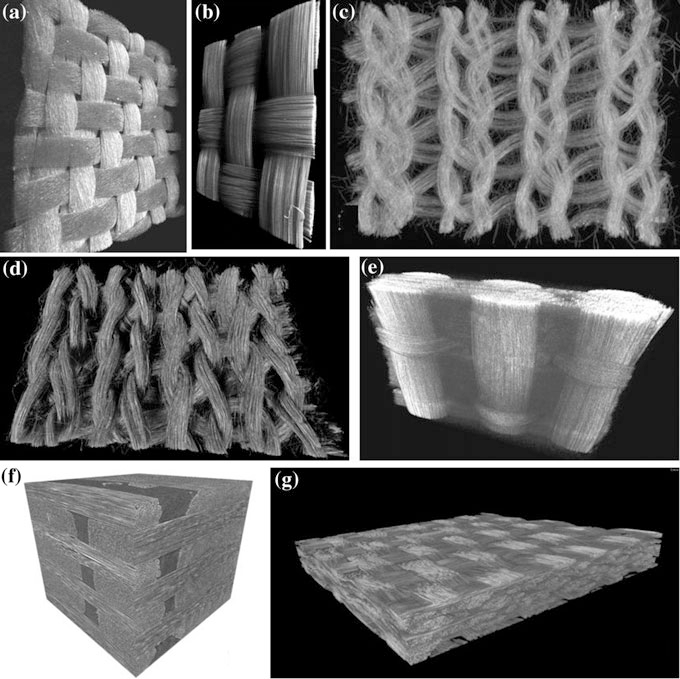

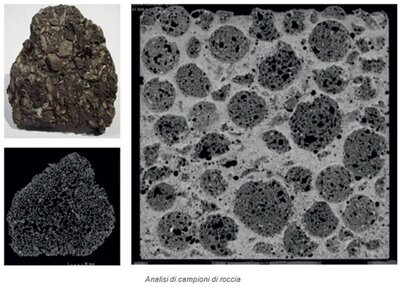

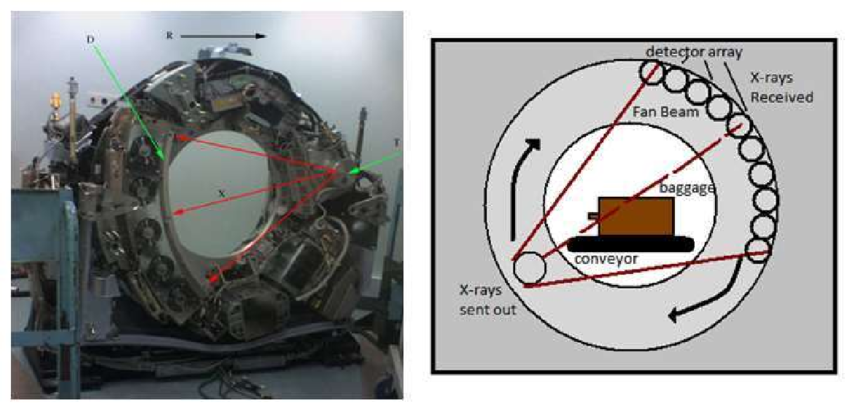

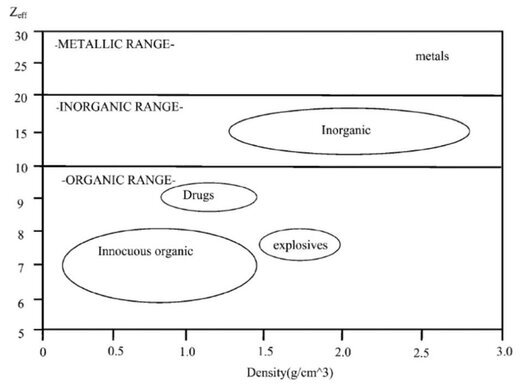

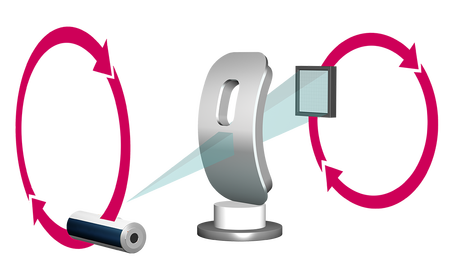

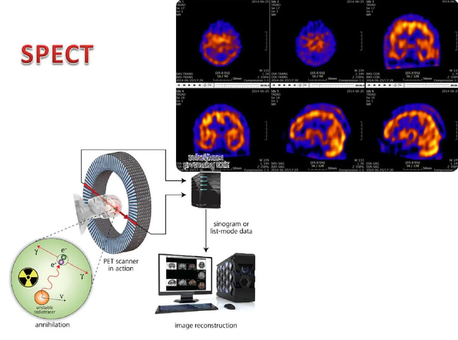

"Tomographic Systems for Different Applications"The technology allows for the identification of internal cracks, fusion defects, and other anomalies that could compromise safety and operational efficiency.Detailed three-dimensional images enable precise assessment of the structural integrity of turbines, preventing potential catastrophic failures and enhancing predictive maintenance.In the automotive industry, CT is used to examine engines and mechanical components.This process ensures that each part meets stringent quality and safety standards before being assembled into a vehicle." Visualization of the Benefits of Using Quality"The ability to detect internal defects, such as material porosity, misalignments, and other imperfections, is crucial to ensuring that finished products are safe and reliable.In summary, Computed Tomography is an essential tool in modern industry for the inspection, analysis, and maintenance of critical components, improving production process efficiency and ensuring product quality and safety."High-Speed and High-Resolution Rotating System"2. Cone Beam Computed Tomography (CBCT)Cone Beam Computed Tomography (CBCT) is an innovative technology widely used across various industrial sectors for the three-dimensional scanning of small components with high detail.This technique offers numerous advantages over traditional imaging methods, as it allows for the acquisition of high-resolution images in shorter time frames, enhancing inspection process efficiency.For example, in the manufacturing industry, CBCT is particularly useful for inspecting 3D-printed components."View of the beginning of an implant (CBCT)"Thanks to its ability to detect printing defects, such as porosity, misalignments, and surface imperfections, CBCT helps ensure that final products meet the required quality standards.This is crucial in a context where even the smallest defect can compromise the functionality of a component. Additionally, CBCT is applied in the materials industry, where it is used for the analysis of microstructures.This technology allows the internal composition of composite materials and metals to be studied, providing valuable information about their integrity and performance.As a result, CBCT plays a key role in ensuring the quality and reliability of products, helping to enhance companies' competitiveness in the global market.Cone beam CT has become increasingly important in treatment planning and diagnosis in implantology, and it is particularly essential in computer-assisted implantology techniques."Orthodontic image view (CBCT)"3. Positron Emission Tomography (PET)Positron Emission Tomography (PET) is an advanced imaging technique that is finding increasing applications in the industrial sector, particularly for research and development of new materials and production processes.This technology leverages the emission of positrons from radioactive isotopes to create detailed three-dimensional images, allowing scientists and engineers to study phenomena and processes in a non-invasive way.A significant example of PET's use in the industrial field is the study of fluid distribution and dynamics within chemical reactors.Thanks to its ability to track the movement of fluids labeled with radioactive isotopes, PET provides valuable information about flow patterns and stagnation zones inside reactors.This allows for the optimization of reactor design and improves the efficiency of production processes, reducing waste and increasing product yield.Additionally, PET can be used to monitor the degradation of polymeric materials in real-time, providing crucial insights for the development of more durable and resilient materials.By tracing the diffusion of radioactive tracers within polymers subjected to thermal or mechanical stress, it is possible to identify degradation mechanisms and develop improved formulations.Although the use of PET in the industrial field is still limited compared to the medical field, its potential is widely recognized.With technological advancements and the increased availability of suitable radioactive isotopes for industrial applications, it is likely that the use of PET will further expand in the coming years, helping to drive innovation and optimize production processes across various industrial sectors."Breakdown of the main operators in the global market for this technology"4. Single Photon Emission Computed Tomography (SPECT)Single Photon Emission Computed Tomography (SPECT) is an advanced imaging technique applied in various industrial sectors, particularly in the study of the distribution of radioactive isotopes in industrial processes.This technology enables detailed three-dimensional imaging, providing valuable insights into the dynamics of materials and fluids.A significant example of SPECT usage is in the oil industry, where it is employed to track the distribution of radioactive tracers in oil wells.This application is essential for optimizing hydrocarbon production, as it helps identify accumulation and flow areas, thus improving recovery efficiency.Thanks to its ability to provide real-time information, SPECT represents a valuable tool for improving industrial processes and operational safety.5. Electron Beam Computed Tomography (EBCT)Electron Beam Computed Tomography (EBCT) is an advanced technology used to quickly inspect critical industrial components, providing a non-destructive method for analyzing the quality and integrity of materials.This technique is particularly valued in the automotive industry, where it is employed to examine engine blocks and other essential components.Due to its ability to rapidly detect internal defects such as cracks, inclusions, or structural imperfections, EBCT allows for real-time quality control.The speed of image acquisition is one of EBCT's major advantages, as it enables quality checks to be integrated directly into the production line.This not only enhances production efficiency but also ensures component reliability, reducing the risk of operational failures.Additionally, EBCT can provide high-resolution images that allow for detailed analysis of the internal geometry of components, facilitating the diagnosis of potential problems before they become critical.Beyond the automotive industry, EBCT is also used in other sectors, such as aerospace and electronic equipment manufacturing, where quality and safety are of paramount importance.With the evolution of technology, EBCT continues to be a crucial tool for improving production processes and ensuring high-quality standards."Siemens EBCT system used in the medical field"6. Dual-Energy Computed Tomography (DSCT)Dual-Energy Computed Tomography (DSCT) is a cutting-edge technology used in industry for high-speed material analysis, offering rapid and detailed results.This technique is particularly useful in critical sectors, such as energy production, where safety and reliability are paramount.For example, in monitoring high-pressure pipelines, DSCT enables real-time surveillance, detecting defects and corrosion before they can lead to catastrophic failures.The ability to acquire high-resolution images quickly is one of the main advantages of DSCT.This not only improves operational safety but also allows for more effective risk management, reducing downtime and maintenance costs.Additionally, continuous analysis of infrastructure conditions enables the planning of preventive maintenance, avoiding costly plant shutdowns and ensuring optimal operation.DSCT is also applied in other sectors, such as the automotive and aerospace industries, where ensuring the quality and integrity of components is crucial.With technological advancements, the use of DSCT is expected to grow, contributing to improved efficiency and safety across various industrial fields."Principles and Applications of Dual Source CT"7. Micro-Computed Tomography (micro-CT)Micro-Computed Tomography (micro-CT) provides very high resolution, allowing for detailed visualization of internal structures at a microscopic level.Primarily used in scientific research and pre-clinical studies, micro-CT is employed for the analysis of small animals, materials, and tissues." Micro-CT images of cellular materials:(a) balsa wood (natural honeycomb), (b) open-cell foam, (c) closed-cell foam"Micro-Computed Tomography (micro-CT) is an advanced technology that offers extremely high resolution, allowing for detailed visualization of internal structures at a microscopic level.This technique is particularly valued in scientific research and pre-clinical studies, where it is used to analyze a wide range of samples, including small animals, materials, and biological tissues.Micro-CT is particularly useful for studying bone architecture, as it allows for unprecedented detail in examining bone density and structure.Additionally, it is employed in cardiovascular disease research, enabling visualization of vascular structures and any anomalies that may affect heart health.This technology is also crucial in the development of new materials, as it provides detailed information on microstructure, helping researchers design materials with optimized properties.Thanks to its ability to provide detailed three-dimensional images, micro-CT is essential for understanding microscopic pathologies and evaluating new treatments and medical devices.With the continuous evolution of technology, micro-CT is becoming a critical tool in biomedical research, enhancing scientific knowledge and fostering innovations in the field of medicine."High-power microfocus from Comet-Yxlon at 225 keV"8. Nano-Computed Tomography (Nano-CT)Nano-Computed Tomography (Nano-CT) represents a significant advancement over Micro-CT, offering even higher spatial resolution that makes it essential for the detailed analysis of microstructures in advanced materials.This non-destructive imaging technology uses high-energy X-rays to acquire extremely high-resolution images, allowing for precise visualization and characterization of the nanometric features of the analyzed samples."Micro-CT images of tissues and textile composites:(a) flax; (b) glass fiber fabrics; (c) glass; (d) knitted steel fiber fabrics; (e) glass fiber fabrics;(f) 3D carbon fiber fabrics; (g) woven alumina fiber laminate""Viewing and analysis of a rock sample"In industry, Nano-CT is applied to the in-depth study of innovative materials and miniaturized components, where the ability to analyze nanometric-scale structures is crucial for fully understanding their properties and performance.For example, this technique is used to inspect high-precision electronic devices, such as microprocessors and MEMS (Micro-Electro-Mechanical Systems), allowing for the detection of defects and anomalies at the submicroscopic level that could affect the proper functioning of the components.Additionally, Nano-CT is a valuable tool for characterizing advanced composite materials, where the distribution and interaction between different phases at the nanometric level play a crucial role in determining their mechanical, thermal, and electrical performance.Thanks to its ability to provide three-dimensional images with extremely high resolution, Nano-CT enables precise assessment of parameters such as porosity, particle size, and reinforcement morphology, contributing to the development of increasingly high-performance materials.In summary, Nano-Computed Tomography represents an advanced and versatile tool for non-destructive analysis of materials and components at the nanometric scale, ensuring that every detail is accurately evaluated to enhance the performance and reliability of final products."High-power nanofocus from Comet-Yxlon at 190 keV"9. Dual-Energy Computed Tomography (DECT)Dual-Energy Computed Tomography (DECT) is an advanced technique that uses two X-ray energy levels to differentiate between different materials within an object.This ability to distinguish materials is particularly useful in security applications, where DECT is employed to identify hazardous or contraband materials within complex industrial objects.By using two X-ray beams with different energies, DECT can detect and classify materials based on their attenuation properties, providing valuable information for identifying potential threats or irregularities.Specifically, this technology is used in airport and customs security checks, allowing for rapid and accurate analysis of luggage and shipments, helping to prevent the trafficking of illegal and dangerous substances.In addition to security applications, DECT is also used in other industrial sectors, such as energy production, where it can monitor the composition and integrity of nuclear fuels.Moreover, DECT is utilized in manufacturing for inspecting complex components, enabling the identification of internal defects and ensuring the quality of final products.These tomographic technologies, initially developed for the medical field, have been adapted and refined for industrial needs, improving product quality, safety, and reliability.From predictive maintenance to research and development, tomographic techniques are revolutionizing production processes, significantly contributing to technological innovation and industrial efficiency.With the ongoing evolution of technology, it is likely that the use of these techniques will expand further, opening new frontiers for process optimization and enhancing company competitiveness."Tomographic system for baggage inspection"The technology used, called "dual-energy X-ray imaging," employs two different energy sources to provide information about material composition and enhance image contrast.The combination of the two energy values allows for distinguishing objects and estimating with high spatial resolution both the mass density (ρ) and the atomic number (Z) of all constituent elements and compounds in the inspected area.Dual-energy systems also enable the estimation of atomic numbers of materials in luggage, which allows for distinguishing materials based on their chemical composition rather than just variations in density.However, the method has a significant limitation: the actual density of objects in the luggage is often unknown, meaning the system only generates an estimate of the effective atomic number (Z_eff)."Indication of the atomic number position of the various component groups"The collected data is then processed by an artificial intelligence system, which uses advanced algorithms to identify and analyze objects within the luggage.This system has been trained on a wide range of objects and materials, allowing it to easily identify potentially dangerous items such as weapons, explosives, and hazardous chemicals.Once the artificial intelligence system has completed the analysis of the luggage, a two-dimensional image of the luggage contents is generated and displayed on a screen.10. Laminography (CL)Laminography is an advanced imaging technique that allows for the visualization of specific planes within an object using X-rays angled relative to the object itself.This method is particularly useful in the electronics industry, where it is employed for inspecting multilayer printed circuit boards.Thanks to its ability to penetrate materials and provide detailed images of internal structures, laminography enables the identification of critical defects, such as cold solder joints, broken connections, and other anomalies that could compromise the functionality of electronic devices.

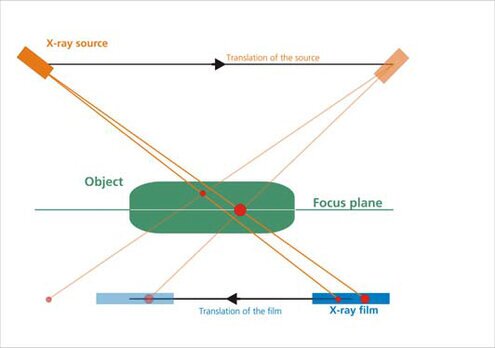

"Tomographic Systems for Different Applications"The technology allows for the identification of internal cracks, fusion defects, and other anomalies that could compromise safety and operational efficiency.Detailed three-dimensional images enable precise assessment of the structural integrity of turbines, preventing potential catastrophic failures and enhancing predictive maintenance.In the automotive industry, CT is used to examine engines and mechanical components.This process ensures that each part meets stringent quality and safety standards before being assembled into a vehicle." Visualization of the Benefits of Using Quality"The ability to detect internal defects, such as material porosity, misalignments, and other imperfections, is crucial to ensuring that finished products are safe and reliable.In summary, Computed Tomography is an essential tool in modern industry for the inspection, analysis, and maintenance of critical components, improving production process efficiency and ensuring product quality and safety."High-Speed and High-Resolution Rotating System"2. Cone Beam Computed Tomography (CBCT)Cone Beam Computed Tomography (CBCT) is an innovative technology widely used across various industrial sectors for the three-dimensional scanning of small components with high detail.This technique offers numerous advantages over traditional imaging methods, as it allows for the acquisition of high-resolution images in shorter time frames, enhancing inspection process efficiency.For example, in the manufacturing industry, CBCT is particularly useful for inspecting 3D-printed components."View of the beginning of an implant (CBCT)"Thanks to its ability to detect printing defects, such as porosity, misalignments, and surface imperfections, CBCT helps ensure that final products meet the required quality standards.This is crucial in a context where even the smallest defect can compromise the functionality of a component. Additionally, CBCT is applied in the materials industry, where it is used for the analysis of microstructures.This technology allows the internal composition of composite materials and metals to be studied, providing valuable information about their integrity and performance.As a result, CBCT plays a key role in ensuring the quality and reliability of products, helping to enhance companies' competitiveness in the global market.Cone beam CT has become increasingly important in treatment planning and diagnosis in implantology, and it is particularly essential in computer-assisted implantology techniques."Orthodontic image view (CBCT)"3. Positron Emission Tomography (PET)Positron Emission Tomography (PET) is an advanced imaging technique that is finding increasing applications in the industrial sector, particularly for research and development of new materials and production processes.This technology leverages the emission of positrons from radioactive isotopes to create detailed three-dimensional images, allowing scientists and engineers to study phenomena and processes in a non-invasive way.A significant example of PET's use in the industrial field is the study of fluid distribution and dynamics within chemical reactors.Thanks to its ability to track the movement of fluids labeled with radioactive isotopes, PET provides valuable information about flow patterns and stagnation zones inside reactors.This allows for the optimization of reactor design and improves the efficiency of production processes, reducing waste and increasing product yield.Additionally, PET can be used to monitor the degradation of polymeric materials in real-time, providing crucial insights for the development of more durable and resilient materials.By tracing the diffusion of radioactive tracers within polymers subjected to thermal or mechanical stress, it is possible to identify degradation mechanisms and develop improved formulations.Although the use of PET in the industrial field is still limited compared to the medical field, its potential is widely recognized.With technological advancements and the increased availability of suitable radioactive isotopes for industrial applications, it is likely that the use of PET will further expand in the coming years, helping to drive innovation and optimize production processes across various industrial sectors."Breakdown of the main operators in the global market for this technology"4. Single Photon Emission Computed Tomography (SPECT)Single Photon Emission Computed Tomography (SPECT) is an advanced imaging technique applied in various industrial sectors, particularly in the study of the distribution of radioactive isotopes in industrial processes.This technology enables detailed three-dimensional imaging, providing valuable insights into the dynamics of materials and fluids.A significant example of SPECT usage is in the oil industry, where it is employed to track the distribution of radioactive tracers in oil wells.This application is essential for optimizing hydrocarbon production, as it helps identify accumulation and flow areas, thus improving recovery efficiency.Thanks to its ability to provide real-time information, SPECT represents a valuable tool for improving industrial processes and operational safety.5. Electron Beam Computed Tomography (EBCT)Electron Beam Computed Tomography (EBCT) is an advanced technology used to quickly inspect critical industrial components, providing a non-destructive method for analyzing the quality and integrity of materials.This technique is particularly valued in the automotive industry, where it is employed to examine engine blocks and other essential components.Due to its ability to rapidly detect internal defects such as cracks, inclusions, or structural imperfections, EBCT allows for real-time quality control.The speed of image acquisition is one of EBCT's major advantages, as it enables quality checks to be integrated directly into the production line.This not only enhances production efficiency but also ensures component reliability, reducing the risk of operational failures.Additionally, EBCT can provide high-resolution images that allow for detailed analysis of the internal geometry of components, facilitating the diagnosis of potential problems before they become critical.Beyond the automotive industry, EBCT is also used in other sectors, such as aerospace and electronic equipment manufacturing, where quality and safety are of paramount importance.With the evolution of technology, EBCT continues to be a crucial tool for improving production processes and ensuring high-quality standards."Siemens EBCT system used in the medical field"6. Dual-Energy Computed Tomography (DSCT)Dual-Energy Computed Tomography (DSCT) is a cutting-edge technology used in industry for high-speed material analysis, offering rapid and detailed results.This technique is particularly useful in critical sectors, such as energy production, where safety and reliability are paramount.For example, in monitoring high-pressure pipelines, DSCT enables real-time surveillance, detecting defects and corrosion before they can lead to catastrophic failures.The ability to acquire high-resolution images quickly is one of the main advantages of DSCT.This not only improves operational safety but also allows for more effective risk management, reducing downtime and maintenance costs.Additionally, continuous analysis of infrastructure conditions enables the planning of preventive maintenance, avoiding costly plant shutdowns and ensuring optimal operation.DSCT is also applied in other sectors, such as the automotive and aerospace industries, where ensuring the quality and integrity of components is crucial.With technological advancements, the use of DSCT is expected to grow, contributing to improved efficiency and safety across various industrial fields."Principles and Applications of Dual Source CT"7. Micro-Computed Tomography (micro-CT)Micro-Computed Tomography (micro-CT) provides very high resolution, allowing for detailed visualization of internal structures at a microscopic level.Primarily used in scientific research and pre-clinical studies, micro-CT is employed for the analysis of small animals, materials, and tissues." Micro-CT images of cellular materials:(a) balsa wood (natural honeycomb), (b) open-cell foam, (c) closed-cell foam"Micro-Computed Tomography (micro-CT) is an advanced technology that offers extremely high resolution, allowing for detailed visualization of internal structures at a microscopic level.This technique is particularly valued in scientific research and pre-clinical studies, where it is used to analyze a wide range of samples, including small animals, materials, and biological tissues.Micro-CT is particularly useful for studying bone architecture, as it allows for unprecedented detail in examining bone density and structure.Additionally, it is employed in cardiovascular disease research, enabling visualization of vascular structures and any anomalies that may affect heart health.This technology is also crucial in the development of new materials, as it provides detailed information on microstructure, helping researchers design materials with optimized properties.Thanks to its ability to provide detailed three-dimensional images, micro-CT is essential for understanding microscopic pathologies and evaluating new treatments and medical devices.With the continuous evolution of technology, micro-CT is becoming a critical tool in biomedical research, enhancing scientific knowledge and fostering innovations in the field of medicine."High-power microfocus from Comet-Yxlon at 225 keV"8. Nano-Computed Tomography (Nano-CT)Nano-Computed Tomography (Nano-CT) represents a significant advancement over Micro-CT, offering even higher spatial resolution that makes it essential for the detailed analysis of microstructures in advanced materials.This non-destructive imaging technology uses high-energy X-rays to acquire extremely high-resolution images, allowing for precise visualization and characterization of the nanometric features of the analyzed samples."Micro-CT images of tissues and textile composites:(a) flax; (b) glass fiber fabrics; (c) glass; (d) knitted steel fiber fabrics; (e) glass fiber fabrics;(f) 3D carbon fiber fabrics; (g) woven alumina fiber laminate""Viewing and analysis of a rock sample"In industry, Nano-CT is applied to the in-depth study of innovative materials and miniaturized components, where the ability to analyze nanometric-scale structures is crucial for fully understanding their properties and performance.For example, this technique is used to inspect high-precision electronic devices, such as microprocessors and MEMS (Micro-Electro-Mechanical Systems), allowing for the detection of defects and anomalies at the submicroscopic level that could affect the proper functioning of the components.Additionally, Nano-CT is a valuable tool for characterizing advanced composite materials, where the distribution and interaction between different phases at the nanometric level play a crucial role in determining their mechanical, thermal, and electrical performance.Thanks to its ability to provide three-dimensional images with extremely high resolution, Nano-CT enables precise assessment of parameters such as porosity, particle size, and reinforcement morphology, contributing to the development of increasingly high-performance materials.In summary, Nano-Computed Tomography represents an advanced and versatile tool for non-destructive analysis of materials and components at the nanometric scale, ensuring that every detail is accurately evaluated to enhance the performance and reliability of final products."High-power nanofocus from Comet-Yxlon at 190 keV"9. Dual-Energy Computed Tomography (DECT)Dual-Energy Computed Tomography (DECT) is an advanced technique that uses two X-ray energy levels to differentiate between different materials within an object.This ability to distinguish materials is particularly useful in security applications, where DECT is employed to identify hazardous or contraband materials within complex industrial objects.By using two X-ray beams with different energies, DECT can detect and classify materials based on their attenuation properties, providing valuable information for identifying potential threats or irregularities.Specifically, this technology is used in airport and customs security checks, allowing for rapid and accurate analysis of luggage and shipments, helping to prevent the trafficking of illegal and dangerous substances.In addition to security applications, DECT is also used in other industrial sectors, such as energy production, where it can monitor the composition and integrity of nuclear fuels.Moreover, DECT is utilized in manufacturing for inspecting complex components, enabling the identification of internal defects and ensuring the quality of final products.These tomographic technologies, initially developed for the medical field, have been adapted and refined for industrial needs, improving product quality, safety, and reliability.From predictive maintenance to research and development, tomographic techniques are revolutionizing production processes, significantly contributing to technological innovation and industrial efficiency.With the ongoing evolution of technology, it is likely that the use of these techniques will expand further, opening new frontiers for process optimization and enhancing company competitiveness."Tomographic system for baggage inspection"The technology used, called "dual-energy X-ray imaging," employs two different energy sources to provide information about material composition and enhance image contrast.The combination of the two energy values allows for distinguishing objects and estimating with high spatial resolution both the mass density (ρ) and the atomic number (Z) of all constituent elements and compounds in the inspected area.Dual-energy systems also enable the estimation of atomic numbers of materials in luggage, which allows for distinguishing materials based on their chemical composition rather than just variations in density.However, the method has a significant limitation: the actual density of objects in the luggage is often unknown, meaning the system only generates an estimate of the effective atomic number (Z_eff)."Indication of the atomic number position of the various component groups"The collected data is then processed by an artificial intelligence system, which uses advanced algorithms to identify and analyze objects within the luggage.This system has been trained on a wide range of objects and materials, allowing it to easily identify potentially dangerous items such as weapons, explosives, and hazardous chemicals.Once the artificial intelligence system has completed the analysis of the luggage, a two-dimensional image of the luggage contents is generated and displayed on a screen.10. Laminography (CL)Laminography is an advanced imaging technique that allows for the visualization of specific planes within an object using X-rays angled relative to the object itself.This method is particularly useful in the electronics industry, where it is employed for inspecting multilayer printed circuit boards.Thanks to its ability to penetrate materials and provide detailed images of internal structures, laminography enables the identification of critical defects, such as cold solder joints, broken connections, and other anomalies that could compromise the functionality of electronic devices. "Laminography scanning clearly shows the pads and traces of BGAs." "View of the connection micro-wires of an integrated circuit"This technology, originally developed for medical applications, has been adapted and refined to meet the specific needs of the industry.Laminography not only improves product quality but also contributes to their safety and reliability.Additionally, due to its non-destructive nature, it allows for inspections without compromising the integrity of the analyzed components.From predictive maintenance to research and development, tomographic techniques like laminography are revolutionizing production processes."The laminography scan shows the movement made by the emitter and the receiver."These innovations significantly contribute to industrial efficiency and technological innovation, allowing companies to remain competitive in a continuously evolving market. With the increasing complexity of products, the importance of laminography and other imaging techniques will continue to grow, ensuring that companies can tackle future challenges with greater confidence and precision."Internal view of the Comet Yxlon Cheetah system"11. Single Photon Emission Computed Tomography (SPECT/CTA)The combination of Single Photon Emission Computed Tomography (SPECT) and Computed Tomography (SPECT/CTA) represents an innovative approach for the detailed assessment of material flows and structures.This synergy between the two techniques provides valuable and in-depth information, making it particularly useful in various industrial sectors.A significant example is the construction industry, where SPECT/CTA can be used to analyze reinforced concrete structures.By employing this combination, it is possible to detect any defects, such as cracks, voids, or other anomalies within the structures, thus ensuring structural safety.The ability to visualize both internal and external characteristics of materials gives engineers and architects a more comprehensive understanding of the condition of structures, allowing for targeted and timely interventions.Additionally, SPECT/CTA enhances the quality of construction, helping to prevent potential structural problems that could arise over time.This advanced technology not only increases the safety of buildings but also provides added value in terms of efficiency and sustainability.With the ongoing evolution of imaging techniques, the application of SPECT/CTA is expected to grow, opening new opportunities to ensure the quality and reliability of modern infrastructure.- Benefits and Future Prospects of Tomographic TechniquesTomographic techniques offer numerous benefits, making them indispensable for non-destructive inspections across various industrial sectors.One of the most significant features of tomography is its ability to examine the interior of an object without causing damage, which is crucial for critical components that cannot be compromised during the inspection process.Tomographic techniques provide high-resolution three-dimensional images that allow detailed visualization of internal structures, revealing hidden defects that would not be visible with other inspection methods.This enables a thorough analysis of the composition and internal structure of materials, helping to better understand failure mechanisms and develop predictive maintenance strategies.By identifying defects and anomalies before they cause failures, tomographic techniques help prevent costly and dangerous incidents, which is particularly important in sectors such as aerospace, where safety is paramount.Tomographic inspections can be conducted rapidly, minimizing machine and production process downtime, increasing operational efficiency, and reducing costs associated with inactivity.Furthermore, these techniques are applicable to a wide range of materials and components, from metals to composites, microelectronic components to large industrial assemblies, making them suitable for multiple sectors, including automotive, aerospace, electronics, and energy.Tomographic techniques significantly enhance operational safety by monitoring the condition of materials and components in real-time.This is especially relevant in high-risk industries such as nuclear and oil and gas, where safety is of fundamental importance.Continuous and detailed monitoring allows for timely interventions to prevent failures and improve overall process safety.Looking to the future, the prospects for tomographic techniques are promising, with numerous ongoing technological advancements that are expected to further expand their applications and capabilities."Future Market Report on Tomographic Technologies"The use of artificial intelligence (AI) and machine learning for the analysis of tomographic images is already beginning to transform the field.AI algorithms can analyze large volumes of data more quickly and accurately than humans, identifying patterns and defects that might elude human observation.This will not only enhance inspection accuracy but also enable the automation of many quality control procedures.With advancements in detection technologies and computing capabilities, continuous improvements in tomographic image resolution are anticipated.Additionally, the speed of image acquisition will keep increasing, allowing for faster and more frequent inspections without sacrificing image quality.These technological developments will not only make tomographic techniques more efficient but also expand their applications into new sectors.For instance, in the food industry, tomographic techniques could be used for detailed quality checks of food products, detecting contamination or internal defects.In construction, they could assist in evaluating the quality of building materials and structural safety.The combination of different tomographic techniques may offer significant advantages.For example, integrating computed tomography with magnetic resonance imaging could provide even more detailed images and complementary information about the examined materials.This synergy between different technologies will allow for a more comprehensive and accurate view of industrial components, further improving product quality and safety.With the broader dissemination and adoption of tomographic techniques, it is expected that the costs associated with these technologies will decrease.This will make tomographic inspections more accessible to a wider range of companies, including small and medium-sized manufacturers.Increased accessibility will further stimulate innovation and the adoption of these technologies in new industrial contexts.The development of tomographic systems that allow real-time monitoring during production processes will open new possibilities for quality control and predictive maintenance.This will enable immediate intervention when defects are detected, reducing the risk of failures and improving production efficiency.Moreover, tomographic techniques can contribute to industrial sustainability by reducing waste and optimizing material use.Early detection of defects allows for the correction of issues before they compromise the entire production process, minimizing the need for rework and reducing scrap.

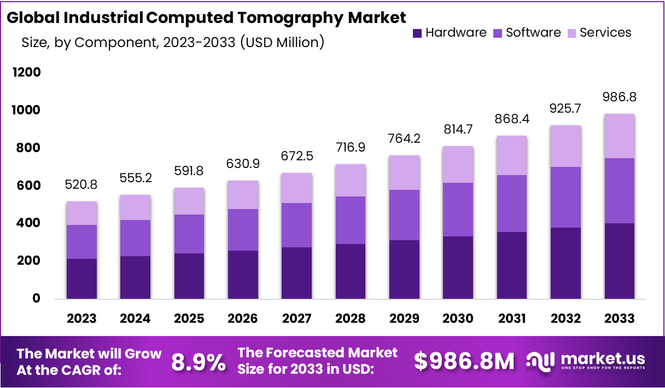

"Laminography scanning clearly shows the pads and traces of BGAs." "View of the connection micro-wires of an integrated circuit"This technology, originally developed for medical applications, has been adapted and refined to meet the specific needs of the industry.Laminography not only improves product quality but also contributes to their safety and reliability.Additionally, due to its non-destructive nature, it allows for inspections without compromising the integrity of the analyzed components.From predictive maintenance to research and development, tomographic techniques like laminography are revolutionizing production processes."The laminography scan shows the movement made by the emitter and the receiver."These innovations significantly contribute to industrial efficiency and technological innovation, allowing companies to remain competitive in a continuously evolving market. With the increasing complexity of products, the importance of laminography and other imaging techniques will continue to grow, ensuring that companies can tackle future challenges with greater confidence and precision."Internal view of the Comet Yxlon Cheetah system"11. Single Photon Emission Computed Tomography (SPECT/CTA)The combination of Single Photon Emission Computed Tomography (SPECT) and Computed Tomography (SPECT/CTA) represents an innovative approach for the detailed assessment of material flows and structures.This synergy between the two techniques provides valuable and in-depth information, making it particularly useful in various industrial sectors.A significant example is the construction industry, where SPECT/CTA can be used to analyze reinforced concrete structures.By employing this combination, it is possible to detect any defects, such as cracks, voids, or other anomalies within the structures, thus ensuring structural safety.The ability to visualize both internal and external characteristics of materials gives engineers and architects a more comprehensive understanding of the condition of structures, allowing for targeted and timely interventions.Additionally, SPECT/CTA enhances the quality of construction, helping to prevent potential structural problems that could arise over time.This advanced technology not only increases the safety of buildings but also provides added value in terms of efficiency and sustainability.With the ongoing evolution of imaging techniques, the application of SPECT/CTA is expected to grow, opening new opportunities to ensure the quality and reliability of modern infrastructure.- Benefits and Future Prospects of Tomographic TechniquesTomographic techniques offer numerous benefits, making them indispensable for non-destructive inspections across various industrial sectors.One of the most significant features of tomography is its ability to examine the interior of an object without causing damage, which is crucial for critical components that cannot be compromised during the inspection process.Tomographic techniques provide high-resolution three-dimensional images that allow detailed visualization of internal structures, revealing hidden defects that would not be visible with other inspection methods.This enables a thorough analysis of the composition and internal structure of materials, helping to better understand failure mechanisms and develop predictive maintenance strategies.By identifying defects and anomalies before they cause failures, tomographic techniques help prevent costly and dangerous incidents, which is particularly important in sectors such as aerospace, where safety is paramount.Tomographic inspections can be conducted rapidly, minimizing machine and production process downtime, increasing operational efficiency, and reducing costs associated with inactivity.Furthermore, these techniques are applicable to a wide range of materials and components, from metals to composites, microelectronic components to large industrial assemblies, making them suitable for multiple sectors, including automotive, aerospace, electronics, and energy.Tomographic techniques significantly enhance operational safety by monitoring the condition of materials and components in real-time.This is especially relevant in high-risk industries such as nuclear and oil and gas, where safety is of fundamental importance.Continuous and detailed monitoring allows for timely interventions to prevent failures and improve overall process safety.Looking to the future, the prospects for tomographic techniques are promising, with numerous ongoing technological advancements that are expected to further expand their applications and capabilities."Future Market Report on Tomographic Technologies"The use of artificial intelligence (AI) and machine learning for the analysis of tomographic images is already beginning to transform the field.AI algorithms can analyze large volumes of data more quickly and accurately than humans, identifying patterns and defects that might elude human observation.This will not only enhance inspection accuracy but also enable the automation of many quality control procedures.With advancements in detection technologies and computing capabilities, continuous improvements in tomographic image resolution are anticipated.Additionally, the speed of image acquisition will keep increasing, allowing for faster and more frequent inspections without sacrificing image quality.These technological developments will not only make tomographic techniques more efficient but also expand their applications into new sectors.For instance, in the food industry, tomographic techniques could be used for detailed quality checks of food products, detecting contamination or internal defects.In construction, they could assist in evaluating the quality of building materials and structural safety.The combination of different tomographic techniques may offer significant advantages.For example, integrating computed tomography with magnetic resonance imaging could provide even more detailed images and complementary information about the examined materials.This synergy between different technologies will allow for a more comprehensive and accurate view of industrial components, further improving product quality and safety.With the broader dissemination and adoption of tomographic techniques, it is expected that the costs associated with these technologies will decrease.This will make tomographic inspections more accessible to a wider range of companies, including small and medium-sized manufacturers.Increased accessibility will further stimulate innovation and the adoption of these technologies in new industrial contexts.The development of tomographic systems that allow real-time monitoring during production processes will open new possibilities for quality control and predictive maintenance.This will enable immediate intervention when defects are detected, reducing the risk of failures and improving production efficiency.Moreover, tomographic techniques can contribute to industrial sustainability by reducing waste and optimizing material use.Early detection of defects allows for the correction of issues before they compromise the entire production process, minimizing the need for rework and reducing scrap.

- Conclusion

Tomographic techniques are profoundly transforming the way industries conduct inspections and quality control on materials and components.These technologies offer numerous advantages, including non-destructive inspection, high-resolution three-dimensional imaging, and detailed analysis of internal structures.Such capabilities not only enhance the understanding of materials and components but also help prevent costly and dangerous failures, increasing the safety and reliability of products.Looking ahead, tomographic techniques are rapidly evolving due to technological advancements and integration with artificial intelligence (AI).AI algorithms are beginning to revolutionize tomographic image analysis, allowing defects and anomalies to be detected with unprecedented speed and precision.It is expected that image resolution capabilities and acquisition speeds will continue to improve, further expanding the applications of these techniques into new sectors such as the food industry and construction.Moreover, combining different tomographic techniques could provide significant advantages, delivering even more detailed images and complementary information.As these technologies become more widespread and adopted, a reduction in costs is anticipated, making tomographic inspections more accessible to small and medium-sized enterprises.This increased accessibility will further stimulate innovation, promoting the adoption of tomographic technologies in new industrial contexts.The future of tomographic techniques is also linked to the development of systems that enable real-time monitoring during production processes.This capability will open new possibilities for quality control and predictive maintenance, allowing for immediate interventions when defects are detected and reducing the risk of failures.Additionally, tomographic techniques will contribute to industrial sustainability by reducing waste and optimizing material use.In conclusion, tomographic techniques are set to become a crucial element in modern industry, providing advanced tools for material inspection and analysis.Their benefits, coupled with promising future prospects, suggest that their role in the industrial sector will continue to grow.With ongoing advancements in imaging technologies and integration with artificial intelligence, tomographic techniques will become even more powerful, efficient, and accessible, making significant contributions to innovation, safety, and industrial sustainability.

- Comet-Yxlon: Global Excellence in Metrological Tomography

With a rich history of innovation and success in the field of metrological tomography, Comet-Yxlon stands as a pillar of the industry, offering reliable and cutting-edge solutions that meet the most demanding requirements of the sector.A Legacy of Excellence: Founded on the heritage of two giants in inspection and metrology—Comet and Yxlon—the company boasts decades of experience and expertise.The merger of these two powerhouses created a unique synergy, leading to the establishment of Comet-Yxlon and solidifying its position as a global leader in metrological tomography.Global Presence: With a well-established presence worldwide, Comet-Yxlon serves a broad spectrum of industrial sectors across the globe.From the automotive and aerospace industries to medical and research applications, Comet-Yxlon’s products are trusted by companies of all sizes for their inspection and measurement needs.Commitment to Innovation: Comet-Yxlon remains at the forefront of innovation in the industry, consistently investing in research and development to anticipate market trends and introduce cutting-edge technological solutions.This ongoing commitment to innovation ensures that Comet-Yxlon's customers have access to the latest technologies and best practices in the field of metrological tomography.

"White Room for Metrological Tomography"Tailored Solutions: Comet-Yxlon understands that each application has unique requirements. Therefore, it offers customized and bespoke solutions to meet the specific needs of its clients.From standard inspection systems to fully personalized solutions, Comet-Yxlon works closely with its clients to ensure that their needs are fully met.Global Quality Standards: Comet-Yxlon is committed to delivering products and services of the highest quality, ensuring compliance with the industry's most stringent standards.Each system undergoes rigorous testing and quality control to guarantee optimal performance and long-term reliability.In conclusion, Comet-Yxlon represents a benchmark in the field of metrological tomography, combining a rich history of success with unparalleled global expertise in the sector.With its global presence, commitment to continuous innovation, and impeccable quality standards, Comet-Yxlon continues to lead the industry toward new frontiers of excellence and performance.

"Comet-Yxlon Tomography and Micro-Tomography Facilities"Xrayconsult is always available to provide information on this technology.To view our facilities, please click on the following link: Industrial TomographyThe information presented in this text is based on authoritative sources and can be verified through the following bibliography:1. "Computed Tomography for Industrial Applications"- Scott A. Miller, 2021

2. "Industrial X-ray Computed Tomography" - Luca Bottani, 2017

3. "Micro-CT: Applications in Materials and Life Sciences" - Anwarul Hasan, 20144. "Nano-CT: Scanning X-Ray Microscopy" - Giorgio Margaritondo, 20155. "Dual-Energy CT in Cardiovascular Imaging" - M.F. Reiser, 20116. "Fundamentals of Laminography" - Michael B. Walker, 20167. "Industrial Tomography: Systems and Applications" - Mi Wang, 20158. "X-ray Computed Tomography in Biomedical Engineering" - Robert C. Smail, 20189. "High-Resolution Micro-CT" - Maryna O. Anatska, 201510. "Nanotomography: Exploring Nanoscale Structures" - O.V. Trushkevych, 201611. "Computed Tomography: Advanced Industrial Applications" - Anders Persson, 201912. "Industrial Applications of X-ray Computed Tomography" - A. Breiby, 201813. "Micro-CT in Materials Characterization" - Matthias Strobl, 202014. "Applications of Industrial Laminography" - John L. Emmett, 201715. "Computed Tomography in Industrial Process Monitoring" - W. R. B. Lionheart, 201416. "3D Imaging Technologies in Industrial Applications" - J. L. Martinez, 201617. "Advances in Computed Tomography for Geomaterials" - F. Beni, 201518. "Tomographic Methods in Non-Destructive Testing" - D. S. Parrott, 201319. "Industrial Computed Tomography: Principles and Applications" - Sven G. Er, 201820. "Advanced Industrial Tomography: Techniques and Applications" - Stephen M. Thompson, 2020The listed sources provide a solid foundation for the information presented and are available for detailed verification of the claims made in the text.